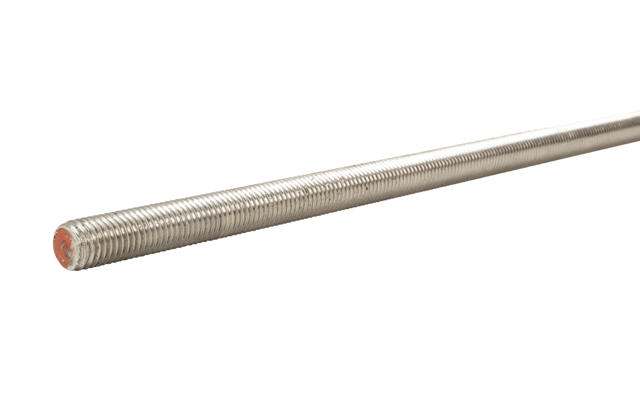

THREADED ROD, DIN 976, 1 METER, STAINLESS STEEL ACID PROOF A4-70

-

Threaded rod is used in all common types of installation where a threaded rod is required. The rod can be cut using a hacksaw or another tool into suitable length, remember that the threads can be easily damaged.

-

Threaded rod DIN 976 (previously DIN 975). The threaded rod is produced in hardened carbon steel with bright zinc plated surface treatment for indoor use and hot dip galvanised and A4-70 acid proof design for outdoor use.

-

In order for a bolted joint to work correctly and be able to counter static and varying loads for long periods the bolts must be preloaded, for example, by tightening with a given torque. Preloading must normally be held to such a level that the combined load in the bolt does not exceed the bolt material’s tensile yield limit. To install threaded rod in class 4.8 you should use a flat washer of at least 140 HV and for a threaded rod in class 8.8 a flat washer of at least HV 200 hardness should be used and it must be tightened with the torque as set out in the Technical data, table 2.

Technical Specification

| Application environment | Outdoors |

| Main Materials | Stainless steel A4 |

| Corrosion resistance class | C5 A4 |

| Standards | DIN 976 |

| Product Data Sheet |

|---|

| Product sheet |